| ||

| Your browser is not supported. | ||

|

Please browse our site using any of the following options:

| ||

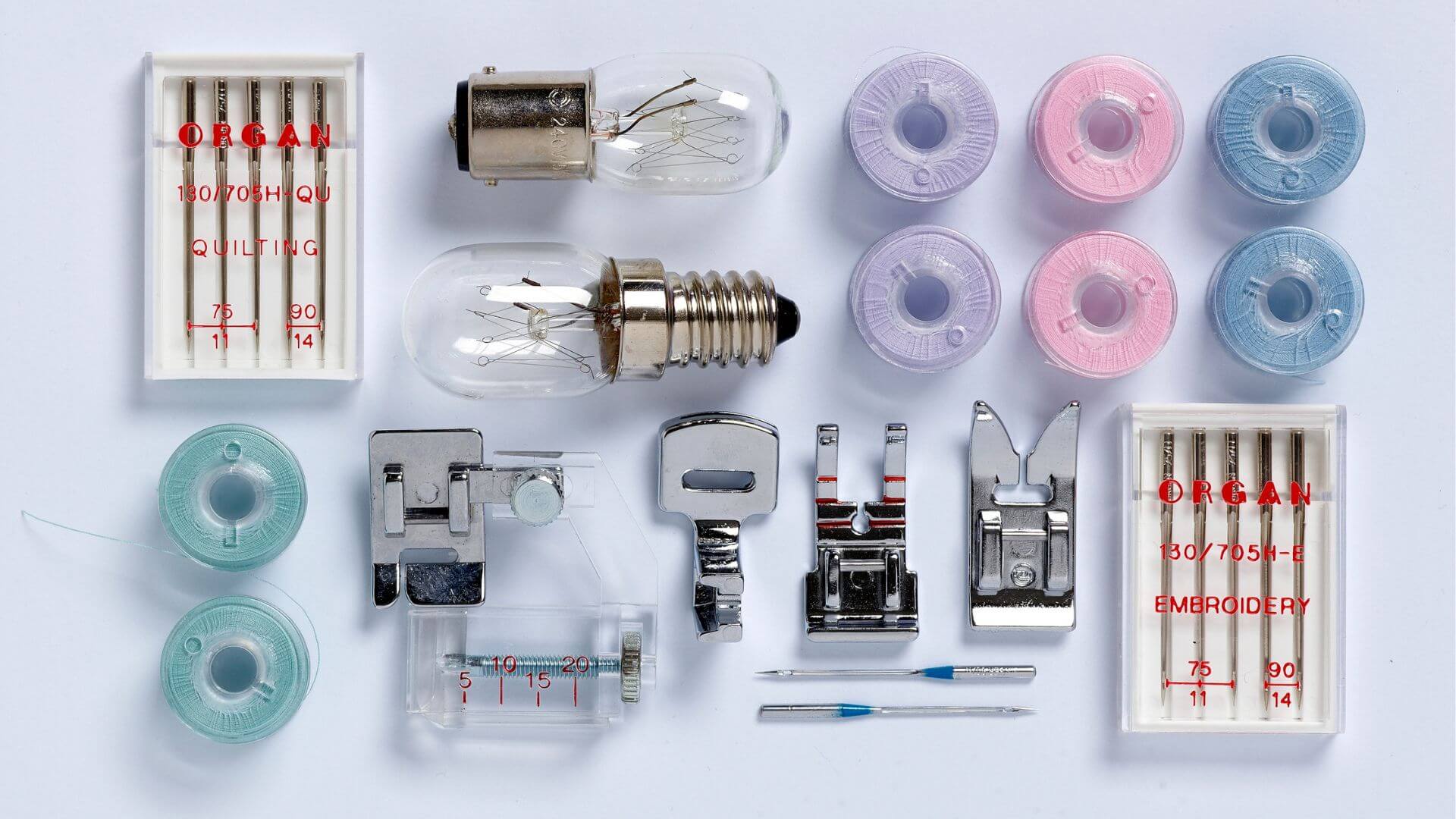

5 Common Sewing Machine Problems & How To Fix Them At Home

Using a sewing machine makes sewing a lot quicker and easier, but with this comes a whole new range of problems we never had to deal with when we sewed using only our hands. Whether you're new to using a sewing machine or you've been using one for years, many of the problems we find with our sewing machines are due to simple reasons that can be fixed at home.

You can find many different sewing machines at Spotlight, and we're familiar with the many different kinds of problems sewists can face when using them. This guide will take you through how to fix five of the most common issues we've found arise when using a sewing machine, all of which can be done at home. But if the problem persists, always take your machine to your local service centre for a professional repair.

1. My Sewing Thread Is Bunching Under The Needle

Also known as 'birdnesting' (when it happens, you'll see why), bunching is when your thread becomes a tangled mess either underneath or sometimes on top of your fabric. You won't always realise it's happening until you look underneath your material, and it can happen to even the most experienced of sewists because the cause isn't always clear.

Bunching can happen when -

- You're using the wrong thread tension. The right tension will ensure your upper and lower threads interlock correctly and produce the same look on either side of the material. If the weight is uneven, then the thread will bunch. Bunching on the bottom, where birdnesting happens the most, occurs when the upper thread's tension is too loose. Use the tension dials to ensure both threads are the same.

- The bobbin underneath your needle isn't inserted correctly. If the bobbin has been inserted backwards or has come out of place, then the thread won't be fed through your machine the right way, which will cause it to bunch. Fix this by removing the bobbin and cleaning the area of any dust and lint. Inspect the bobbin for damage - if it is lopsided or chipped, you'll need a new one - and replace it correctly.

- You are missing your spool cap. The spool cap will keep your thread in place as it is fed through your sewing machine, and if it's not placed correctly or is missing then your spool will bounce and vibrate as it works. When the resulting thread is fed unevenly through your machine, it can bunch under your fabric. Always check your spool cap before you start to sew to ensure it is on securely.

If none of these solutions work, it's always worth giving your machine a good clean and re-threading it. Clean out any lint and dust, oil it if needed, take care of any repairs and replace any cracked, chopped or bent parts. Finish by rethreading the lower and upper threads (keep that tension even!) and you may find the bunching problem has ceased.

2. My Machine Is Skipping Stitches

You may not notice a skipped stitch at first, but if you want to create uniform stitches, then you need to address it quickly. Skipped stitches can be caused by a few different issues, but it usually comes down to the needle. A skipped stitch happens when the hook of your sewing machine misses the loop of thread formed in the eye of the needle that it's supposed to catch. The hook should pass above the eye to catch it, but there are a few factors that can cause it to miss!

Your sewing machine may be skipping stitches if:

- You are using the wrong size or type of sewing needle. If you are using a needle that cannot pierce the material you are working with (like a ballpoint needle for a tough material like leather) then it won't be able to make a new stitch, resulting in a skipped stitch. A needle that is too large or small for the thread you're using can also cause skipped stitches, so always check the thread packaging for its recommended needle size.

- Your sewing needle is bent or blunt. A bent needle means the bobbin won't be able to catch the thread, which will cause your stitches will skip. A blunt needle, like the point above, will not be able to pierce the material you are working with every time, also leading to skipped stitches. Keep fresh needles on hand and always swap them regularly - between projects, or at least every eight hours otherwise.

- The needle bar is out of position. Your needle bar can be knocked out of position when a needle hits the throat plate, or it may simply become loose with time. A needle bar that is out of position will cause the needle to either not go far enough into the bobbin, or to go too far down. Either way can result in skipped stitches. You can rest the needle bar yourself - check by removing the bobbin case and bringing the needle down as far as it can while in the needle bar. Look at the bobbin area at eye height - in the full down position, you should be able to see most of the needle eye, with the top portion obscured. If you can see the whole eye or just the top of it, then your needle bar is out of position.

If none of these solutions work, it may mean the timing of your machine is simply off. This can happen to both manual and computerised sewing machines. Take your sewing machine to your nearest service centre to get the timing corrected.

3. My Needles Are Bending Or Breaking

A needle breaking mid-sew is frustrating, and can be scary if the needle flies out of view! Hunting for half a sewing needle on your floor is never fun, so let's address some of the most common reasons sewing machine needles break and how you can avoid it happening to you.

- Your needle is bent. A bent needle will smack straight into your needle plate and break, which is why it's always important to check your needle before you start to sew. A damaged needle plate can also cause a straight needle to snap.

- You are using the wrong needle type for your material. A needle designed to go through a specific type of material may blunt or break when trying to go through a different kind. You can find ballpoint needles for knit and stretchy fabrics, topstitch needles for use with thicker threads and uniquely tipped leather needles for sewing thick leather and other similar materials. Use these specialty needles for their intended fabric, and use universal needles for everything else.

- Your bobbin case is in the wrong spot. If you haven't correctly inserted your bobbin case, it may be in the way of your needle, so on its downward trajectory the needle may hit the edge of the case and break. Make sure to load the bobbin correctly and lock the case into place so it's out of the way of your needle.

- You have combined the wrong presser foot and needle. There are many different kinds of presser feet, and you need to make sure when using a new one that your needle goes safely through it as it moves up and down. Always position your needle correctly when using a new foot, and test that it can make its way safely through before you start sewing.

Before you start to sew, always inspect your needle to make sure it is straight, sharp and free from any nicks or burrs. A fresh needle is much less likely to break than an old one!

4. My Sewing Thread Keeps Shedding

A thread that sheds as you sew with it can derail your project, and you won't be able to restore the thread once it has unravelled this way. There are a few causes for thread shedding, but none are difficult to fix.

- The needle is too small for the thread. While you may be able to force a large thread through a small needle, this doesn't mean you should sew with it The high speed achieved by a sewing machine will cause the thread to rub against the eye of the needle, causing it to shed, fray and even unravel. Always use the right sized needle for your thread, which you should find recommended on the packaging of your thread.

- There are scratches or nicks in the hole of the presser foot. Whether it's from the needle hitting it or just poor manufacturing, sometimes the hole of your presser foot can have nicks and notches in it. If your thread catches on these it will quickly fray and shed. You can smooth it using fine sandpaper, or simply switch to a fresh presser foot if you see any defects in it.

- The bobbin case is scratched or nicked. Your bobbin case can become misshaped and nicked over time, which will then damage the thread around it, making it prone to shedding and even breaking. Swap out your bobbins once they get a little old and worn to prevent this.

- Your thread is too dry. Dry thread is more prone to shedding and breaking. Your thread can become dry if it is left in direct sunlight or if your house has very dry air. You can use a sewer's silicone lubricant on your thread to fix this, which comes in a drop or spray bottle.

Sometimes you may just have a bad batch of thread or needles. Swap them out when shedding starts to determine if it is the fault of your machine or your components.

5. My Bobbin Thread Keeps Breaking

The bottom thread in your sewing machine, called the bobbin thread, can break for a variety of reasons. Always check your machine has been threaded correctly if your bobbin thread breaks, but if that doesn't solve the issue, then try some of these solutions instead.

- Your bobbin is inserted backwards. Your sewing machine will have its own way it needs the bobbin to be inserted, which it will indicate next to the bobbin case. Whether it's clockwise or counterclockwise, inserting it the wrong way will seem to work for a short while - then your bobbin thread will catch and break.

- There are burrs on your bobbin case or throat plate. Over time, threads will wear burrs into your bobbin case and throat plate, which will weaken your thread until it snaps. You can sand these back using fine sandpaper, then clean your machine for a smooth, catch-free surface for your thread to run against.

- You are using a bobbin incompatible with your sewing machine. Some sewing machines will require you to use bobbins from a specific brand - all will require bobbins of a particular size. Bobbins that are too large won't spin freely in the case, while bobbins that are too small will rattle and bounce around, which can cause the thread to snag and break. Your machine's instructions will indicate what kind of bobbins can be used with it, so check it before buying a new pack to ensure they're compatible.

- Your bobbin tension is too tight. The tension from your upper and lower threads should be the same, otherwise it can cause your threads to snap. Usually you aren't supposed to adjust the tension of your bobbin, but if the thread isn't running smoothly adjust the screw on the side of the case to loosen it using a small screwdriver. If you can't get it right yourself, a sewing machine technician at a service centre can do this for you.

Old bobbins can warp due to heat and become notched - always replace them if you are in doubt of their quality.

Sew With Confidence At Spotlight

We hope these sewing machine solutions have helped you! You can find a great range of sewing machines and sewing supplies online at Spotlight - with our wide range of payment options and home delivery available, you can always get the sewing supplies you need from us. Visit your nearest Spotlight store and our friendly team will help you choose the right sewing supplies for your next project!

For more information, read our buying guides on sewing machines, sewing machine parts and sewing needles and thread. And if you need some sewing inspiration, browse our huge range of sewing projects online!